Paper is an easy-to-process material that finds a number of applications in office work. If you want a specific paper format, you will need to use the right equipment. Find out how to cut paper quickly and conveniently. See what equipment will help you get it to the perfect size.

Paper is a material that can be easily processed. However, if you want to format paper with an accuracy of tenths of a millimetre, it is necessary to use professional cutting tools. Depending on the specific work of the office in question and the number of paper documents used, it is worth equipping the office with the appropriate cutting tools.

In classic offices, the most common type of paper used is the so-called A4 photocopy paper of 70 g/m² or 80 g/m². In advertising agencies, architectural and surveying offices, the standard is to use the larger A3 sheet format and cut it to the desired size. In office work, it is often necessary to use other types of paper as well, e.g. satin paper, photographic paper, office paper, two-ply paper, premium paper, art paper or roll paper.

Before choosing a particular piece of paper-cutting equipment, we must first consider how we will use it. To do this, it is useful to answer the following questions:

The market offers a wide range of classic, professional and creative paper cutting tools. Among the most popular are:

The most popular paper-cutting instrument, which is found on the equipment of almost every office and home. Scissors come in many varieties, including:

These types of knives are most often used for precise and customised trimming of individual sheets of paper. The knives are available in two versions:

Die-cutters are specially shaped pieces of metal with a cutting edge. With the help of special die-cutting machines, we can easily cut out decorative shapes from paper. These types of machines and die-cutters are most often used in the scrapbooking technique.

Punchers and corner rounders are used in homes, offices, archives and anywhere else where small holes in paper documents need to be made quickly. The individual tool types are used to cut holes (round, half-round, oblong) or round off corners.

Popular office equipment that precisely cuts through larger numbers of sheets of paper. Classic guillotines consist of a base and a lever to which a blade is attached that cuts the underlying material as it falls. Guillotines can be equipped with a paper clamp in the form of a strip (metal or plastic), thanks to which the sheets of paper do not move during cutting. Millimetre and/or inch graduations on the base of the guillotine are very helpful in precise paper cutting. With regard to the mechanism of operation we can distinguish:

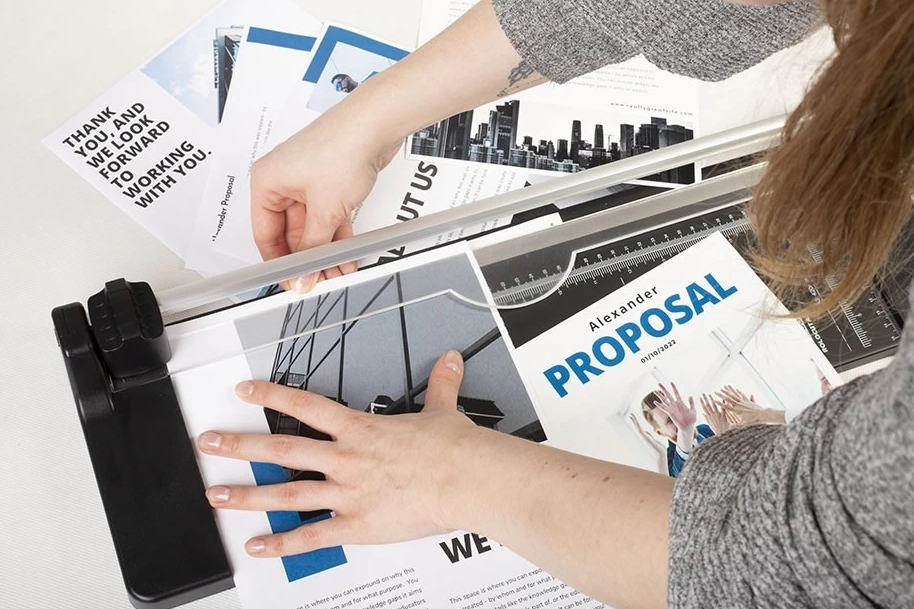

Paper cutters, also known as paper trimmers, are used in offices, binderies and copy shops. The classic office paper cutters can cut approx. 5-10 sheets at a time. The range includes A4 and A3 paper cutters. Based on the method of operation, we distinguish between the following:

They are used to cut paper in rolls. Depending on how large the roll diameter is to be cut, manual, hydraulic or electric feed saws can be used. Paper machines make it possible to cut paper without unrolling the reel. High-end machines are equipped with efficient fork chains with special link geometry to ensure a smooth cutting surface. Special systems for correcting the cutting line, stellite guides and a table for rotating the paper reel are additional features that enhance the work of the paper saws. This type of equipment is mainly used in paper mills.

Cutting sheets of paper to size, formatting invitations and business cards or aligning clipped sheets of paper are just a few examples of the tasks we use office paper cutting tools to perform. Precisely cutting through a thicker layer of paper requires the use of specialised equipment. Here is a list of the main benefits of using the right equipment:

When choosing a cutting machine, it is worth paying attention to its design. Depending on the model chosen, pay attention to:

How often and how you use your cutting equipment has a key impact on which model you should choose. In a domestic environment, if you plan to occasionally use this type of equipment to cut single sheets, small devices with a simple design and a small number of functions will suffice. By contrast, print shops, bookbinding machines and service outlets may require specialised equipment that can withstand heavy use.