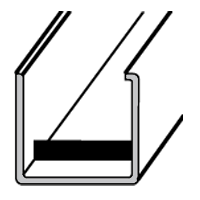

Covers and inserts are held by a metal channel. The back wall of the channel is tilted to hold the covers and pages of documentation. The channel is finished with an elegant veneer or coat of varnish. The special shape of the channel ensures perfect documentation appearance. Documentation insert is not damaged. The front wall never deforms.

Special stoppers makes centering of the documents together with the covers very easy, also prevent the documentation pages from moving along the channel.

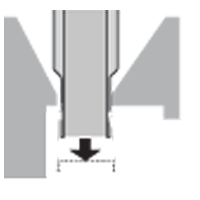

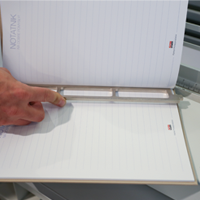

The unique, patented system of special guides “coVer guide” allows you to place documents in a metal channel in a very simple way.

Hard cover binding using O.HARD COVER and O.CHANNEL.

Soft transparent cover binding using O.CLEAR COVER and O.CHANNEL.

Soft cover binding using O.CLEAR and O.UNIVERSAL and O.SIMPLE CHANNEL.

Binding using O.SIMPLE CHANNEL only.

1.5 mm channel

This channel will allow you to bind 1 to 15 sheets of paper*

|

3 mm channel

This channel will allow you to bind 16 to 30 sheets of paper*

|

5 mm channel

This channel will allow you to bind 31 to 40 sheets of paper*

|

7 mm channel

This channel will allow you to bind 41 to 60 sheets of paper*

|

10 mm channel

This channel will allow you to bind 61 to 90 sheets of paper*

|

13 mm channel

This channel will allow you to bind 91 to 120 sheets of paper*

|

16 mm channel

This channel will allow you to bind 121 to 150 sheets of paper*

|

20 mm channel

This channel will allow you to bind 151 to 190 sheets of paper*

|

24 mm channel

This channel will allow you to bind 191 to 220 sheets of paper*

|

28 mm channel

This channel will allow you to bind 221 to 260 sheets of paper*

|

32 mm channel

This channel will allow you to bind 261 to 300 sheets of paper*

|

*test were made on 80 g/m2 paper, however, the values may vary ± 10% depending on the paper fluffing.

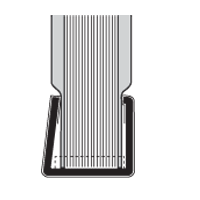

STEP 1 Prepare for the binding: documents, covers and properly selected channel (see the "Channel selection" tab). |

STEP 2 Insert the channel into the binding slot and set it in correct position. |

STEP 3 Align the document file and insert it between the covers. |

STEP 4 Lock the channel with the clamp so that it does not move. |

STEP 5 Place the document file with the covers in the channel. Thanks to patented coVer guide system, it is extremely simple. |

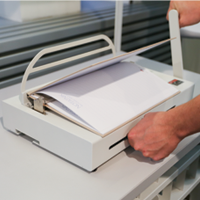

STEP 6 To bind documents, just push the lever. |

STEP 7 Release the binding from the binding slot using the clamp. |

READY! Presitigious binding just in a few seconds! |

The binding process example is shown with the OPUS Atlas 190 equipment.

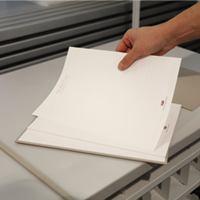

STEP 1 To debind documents, first insert the wedge in the center of the bound documentation. |

STEP 2 After setting up the documentation with the wedge on the debinding jaws, move the lever down several times and the channel will open. |

STEP 3 Documents, covers and channel remain intact and can be re-used. |

STEP 4 Correct the mistake of replace the relevant cards and re-bind it again. |

The debinding process example is shown with the OPUS Atlas 190 equipment.