Electric binding machine

Binding equipment - OPUS MB 300 el-office

- Catalogue number: 646814

Electric binding machine

Binding equipment - OPUS MB 300 el-office

0 (0)

- Catalogue number: 646814

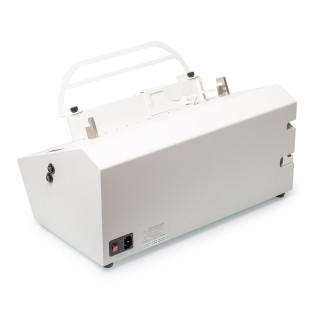

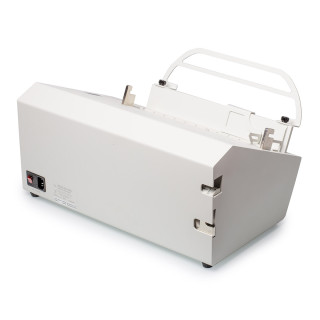

MB 300 EL-OFFICE – MANUAL-ELECTRIC CHANNEL BINDING EQUIPMENT

MB 300 EL-OFFICE is a modern manual-electric equipment for binding and debinding documents up to 300 sheets. The binding equipment operates in the METALBIND system, but after using additional inserts, it can also be used to bind documents in the C-BIND system. The channel in this model is held by special jaws activated by a lever, and the binding process itself is carried out via an electric motor – just press and hold the two buttons located on the side of the housing. The binding force is shown on the display and can be easily changed using the buttons. The solid construction in a metal housing ensures operational stability and durability of the device. The MB 300 EL-OFFICE is recommended for offices and service points where binding is a part of daily work.

CHANNEL BINDING SYSTEMS: METALBIND AND C-BIND

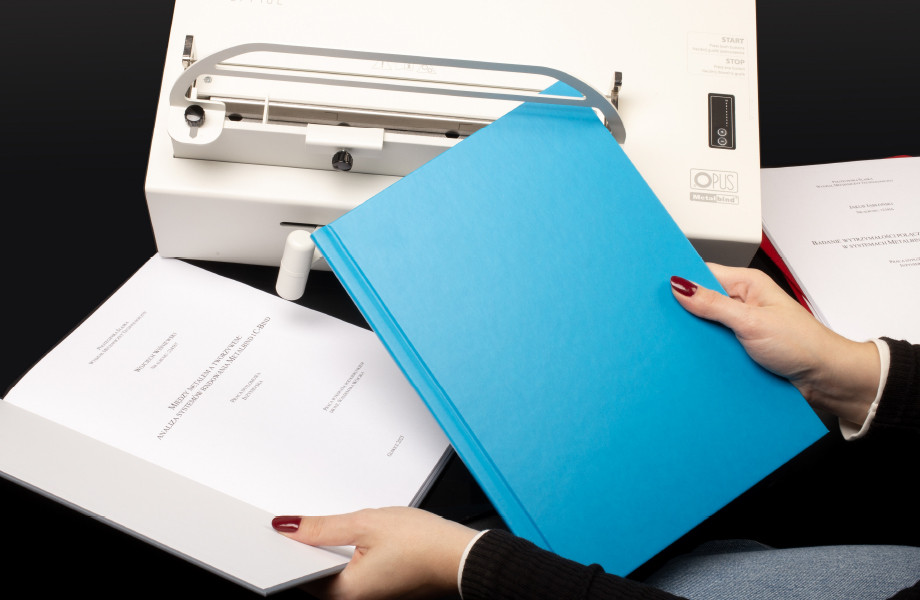

Channel binding systems allow for aesthetic and durable binding of documents without damaging the pages – connecting them with the cover is done without stapling, gluing, or punching the sheets. METALBIND is an innovative system, ensuring a perfect appearance for documents and reliable security. It also leaves freedom in choosing the front and back cover and the channel. The cover and pages are placed in a metal channel, whose angled back wall holds the contents, and the front does not deform – hence binding in the METALBIND system provides the most aesthetic and elegant effect. C-BIND, in turn, is a binding system in which the covers form a single whole together with the channel, which is clamped on both sides. Unlike the METALBIND system, the channel is located inside the cover.

BIND AND DEBIND DOCUMENTS – USING THE SAME MATERIALS

Channel systems enable non-invasive binding – meaning without the need for punching, gluing, or stapling the documents. Thanks to this, all elements of the document – pages, covers, and channels – remain in perfect condition and can be reused after opening the channel. The possibility of debinding and rebinding allows for correcting errors in the document content, adding or removing pages, and replacing covers and channels.

BUTTON OPERATION AND EASY BINDING FORCE ADJUSTMENT

You can operate the device easily and conveniently using the lever and buttons. By releasing the lever, you lock the channel in special jaws, and you carry out the binding process itself by holding both START buttons. The MB 300 EL-OFFICE is equipped with a binding force indicator – using the buttons, you can adjust the clamping force, and the device will remember the last set value to achieve the same repeatable binding results for subsequent documents.

SELECTING THE CHANNEL AND COVER USING A MAGNETIC DEVICE

The binding equipment is equipped with a magnetic selection tool for the channel in the METALBIND system and the cover in the C-BIND system, thanks to which you can easily match the appropriate channel or cover to the number of pages being bound. Precise selection of materials allows for achieving the best binding effects – not only aesthetic but also practical, because if the channel is poorly chosen, pages might fall out, for example. You can attach the tool anywhere on the housing when you are not using it.

A WIDE CHOICE OF COVERS AND BINDING PERSONALIZATION

Using the MB 300 EL-OFFICE, you can bind documents in various types of covers: hard, soft, transparent, in various colors, sizes, and textures. You can use covers from both the METALBIND and C-BIND systems. It is also possible to create a customized cover using dies and fonts – you choose what will be on your cover!

ACCESSORIES AND ADDITIONAL EQUIPMENT

The device comes with accessories for binding and debinding in the METALBIND system: a magnetic tool for selecting the channel/cover size, which can be attached anywhere on the housing; a movable stop for smaller format covers; a debinding wedge and a cover for debinding 1.5 mm – 3 mm channels; a narrow (for channels from 20 to 32 mm) and a wide (for channels up to 16 mm) binding insert. There are special compartments at the back of the device for storing accessories.

NOTE! For the binding equip,ent to work in the C-BIND system, it is necessary to purchase appropriate additional accessories: O.CB Pivot Inserts for Atlas 300 / MB 300 binding insert, O.CB Debinding Tool for Atlas 300 / MB 300 / MBE 300 debinding wedge, and the AA debinding jig for channels.

ADVANTAGES OF THE MB 300 EL-OFFICE CHANNEL BINDING EQUIPMENT

- manual-electric operation: binding performed using buttons

- operation in the METALBIND and C-BIND system

- easy selection of channel and cover sizes

- maximum number of bound sheets: 300 (80 g/m²)

- binding force adjustment

- fast binding

- perfect cover appearance, wide range of covers and channels

- document safety – binding without glue, stapling, or punching

Specification

| Brand | OPUS |

|---|---|

| Binder type | channel |

| Maximum binding format | A3 (short side only) |

| Maximum number of bound pages* | 300 |

| Operation type | seml-electric |

| Metal housing | yes |

| Net weight | 21 kg |

| Gross weight | 23 kg |

| Height | 270 mm |

| Width | 465 mm |

| Depth | 320 mm |

| * tests made on paper | 80 g/m² |

| Device warranty | 2 years |

| Feature / purpose | Manual binding machines, Electric binding machines, Office binding machines |

| Binding system | METALBIND, C-BIND |

Downloads

-

User guide

Format: .PDF, size: 4.4 MB

-

Data sheet

Format: .PDF